Table of Contents

Toggle

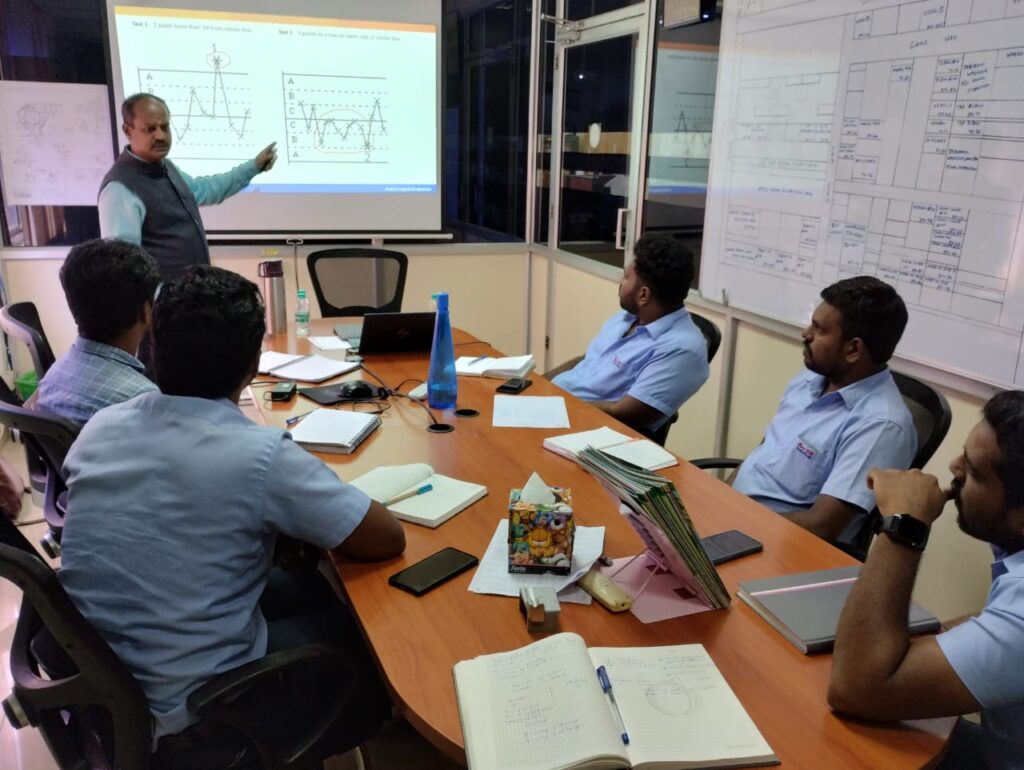

A one day workshop was conducted by Prof.Dr.Gopal Sivakumar

It was a crisp morning in Chennai, and the excitement among the quality engineers of a prestigious manufacturing company was palpable. Prof. Dr. Gopal Sivakumar, a renowned expert in quality management, was set to conduct a one-day workshop that promised to unlock the secrets of achieving excellence in manufacturing through Statistical Process Control (SPC) and Process Capability.

Setting the Stage

The workshop began with a warm welcome from the company’s leadership team. Dr. Sivakumar wasted no time diving into the importance of Statistical Process Control. With a charismatic presence and a wealth of knowledge, he captivated the audience, stressing the significance of monitoring and controlling the manufacturing process to ensure consistent quality.

He explained, “SPC is not just about charts and numbers; it’s a mindset that permeates the entire organization. It’s about understanding the process variations and making informed decisions to enhance product quality.”

Demystifying Statistical Process Control

The participants were taken on a journey through the fundamentals of SPC. Dr. Sivakumar illustrated the power of control charts in visualizing variations in a process over time. The engineers learned how to distinguish between common cause and special cause variations, empowering them to make data-driven decisions.

“SPC is like a detective tool,” Dr. Sivakumar explained. “It helps you uncover the mysteries behind process fluctuations and guides you in making corrections to ensure the desired quality outcome.”

Process Capability: Unleashing the Potential

After a comprehensive session on SPC, the focus shifted to Process Capability. Dr. Sivakumar emphasized that understanding the capability of a process is crucial for predicting and controlling outcomes. The engineers were introduced to key metrics like Cp, Cpk, Pp, and Ppk, which became their compass for gauging process performance.

“Process Capability is about setting realistic expectations for your process,” Dr. Sivakumar stated. “It’s not just about meeting specifications but exceeding them consistently.”

Hands-On Application

Theoretical knowledge was seamlessly translated into practical skills through interactive exercises. The engineers worked on real-life case studies, applying SPC techniques to actual manufacturing scenarios. The room buzzed with discussions as participants collaborated to analyze data and derive meaningful insights.

“Learning by doing is the key to mastery,” Dr. Sivakumar encouraged. “Apply these principles in your daily work, and you’ll see the transformation.”

Building a Culture of Continuous Improvement

As the workshop neared its end, Dr. Sivakumar stressed the importance of fostering a culture of continuous improvement. He urged the engineers to embrace SPC and Process Capability as integral tools in their pursuit of excellence.

“Quality is not an act; it’s a habit,” Dr. Sivakumar concluded. “Make Statistical Process Control and Process Capability part of your organizational DNA, and you’ll pave the way for sustained success.”

The Aftermath

Armed with newfound knowledge and a renewed commitment to quality, the engineers left the workshop with a sense of empowerment. The company, now equipped with a team well-versed in SPC and Process Capability, was poised to elevate its manufacturing processes to new heights, setting the stage for a future of unparalleled excellence.

And so, the one-day workshop became a catalyst for positive change, leaving an indelible mark on the journey toward quality excellence in the bustling manufacturing hub of Chennai.