The Ohmium Manufacturing Facility recently hosted a two-day PFMEA (Process Failure Mode and Effect Analysis) training program, led by Dr. Gopal Sivakumar – a globally recognized Lean & Six Sigma Master Black Belt and expert in process improvement methodologies.

This training marks a significant step towards operational excellence by equipping employees with the skills to identify, analyze, and mitigate process risks before they cause production issues.

Table of Contents

ToggleWhat is PFMEA and Why is it Important in Manufacturing?

PFMEA is a systematic approach to:

- Identify potential failure modes in manufacturing processes.

- Assess the impact, cause, and detection methods of each failure.

- Prioritize risks using the Risk Priority Number (RPN).

- Implement preventive and corrective actions to avoid costly downtime or defects.

In modern manufacturing, where efficiency, quality, and customer satisfaction are critical, PFMEA is not just a compliance requirement – it is a business necessity.

By integrating PFMEA into manufacturing operations, companies can:

✅ Reduce defects and rework

✅ Ensure compliance with ISO 9001 / IATF 16949 standards

✅ Minimize production delays

✅ Boost customer trust and brand reputation

Highlights of the PFMEA Training at Ohmium

The two-day program at Ohmium Manufacturing Facility, Chengalpet covered:

- Understanding the core principles of PFMEA.

- Identifying and mapping process risks in real scenarios.

- Using RPN scoring to prioritize action items.

- Linking PFMEA outcomes to continuous improvement strategies.

- Aligning PFMEA with ISO & IATF compliance requirements.

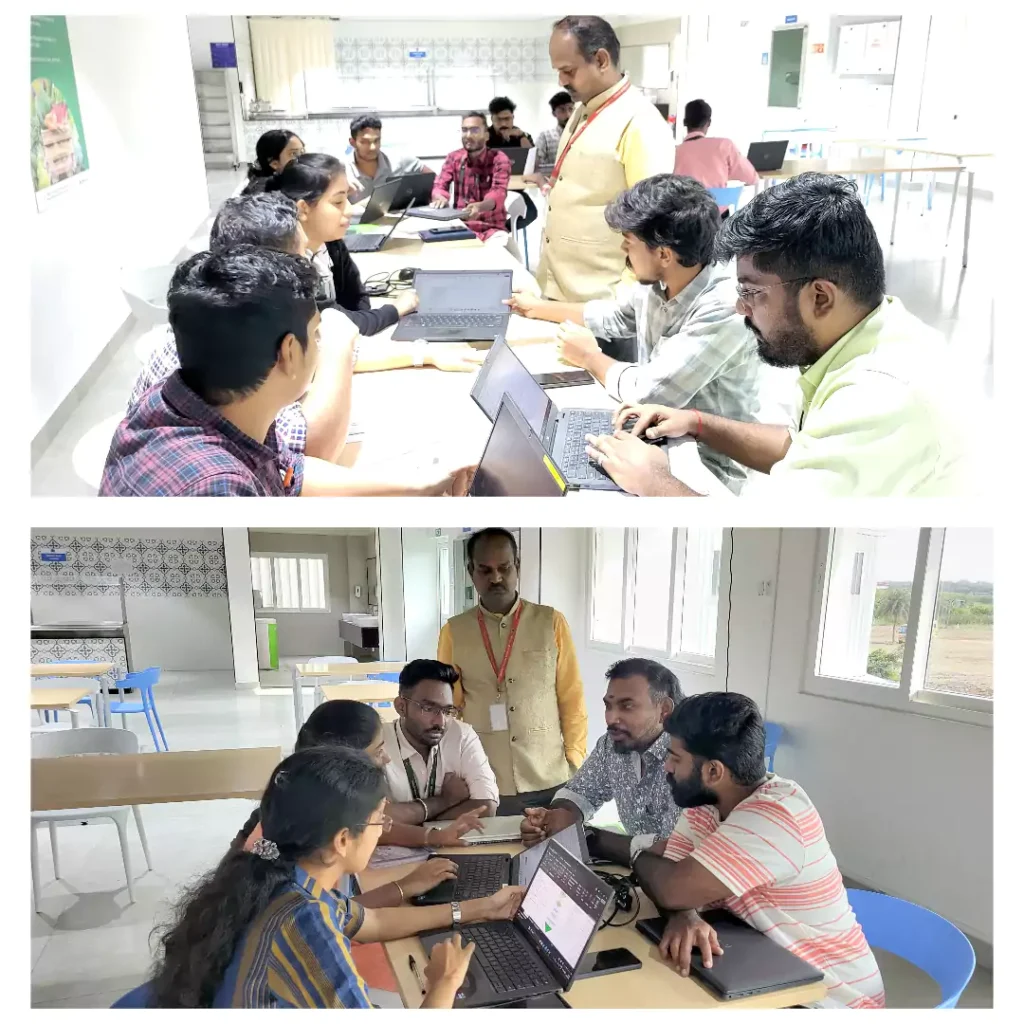

The sessions included interactive group exercises, case studies, and real-time process analysis, ensuring participants could directly relate the learnings to their work environment.

“PFMEA is a forward-looking tool. It helps teams anticipate problems, design out risks, and achieve consistent manufacturing excellence,” said Dr. Gopal Sivakumar.

Ohmium’s Commitment to Quality & Continuous Improvement

We congratulate Ohmium’s management for taking a strategic step towards process reliability and quality improvement. By investing in employee capability building, they are laying a strong foundation for operational excellence.

Special recognition goes to the participants, whose enthusiasm and active engagement reflected a strong commitment to applying PFMEA in their daily operations.

Need PFMEA or Other In-House Training?

If your organization aims to reduce process risks, enhance productivity, and improve quality performance, we offer:

- Corporate In-House PFMEA Training

- Customized Lean Six Sigma Workshops

- Tailored Operational Excellence Programs

Our training solutions are designed to match your industry, process challenges, and improvement goals.

📞 Contact us today to schedule your PFMEA training or to discuss a customized learning plan.

About the Trainer

Dr. Gopal Sivakumar is a Six Sigma Master Black Belt, Lean & Operational Excellence Expert, and a Doctorate in Mechanical Engineering. With over 15,000 professionals trained across various sectors, he brings deep industry experience and practical insights to every program.